NOTICE ON PROCESSING PERSONAL DATA

This notice is to inform you that Trasco S.r.l., with registered headquarters at P.zza Volontari della Libertà n. 8 in Busto Arsizio (VA) and VAT Reg. No. 03281890123, in its capacity as data controller, will process your personal data in line with the methods and purposes outlined below, in accordance with EU Regulation 2016/679 (GDPR) and legislative decree 196/2003 amended by legislative decree 101/2018.

1. SUBJECT MATTER OF THE PROCESSING

The data controller will process personal details (e.g. name, surname, date and place of birth, address, telephone no., e-mail address, ID document details, hereinafter the "Personal Data" or "Data") you provide to carry out activities for the Data Controller (property brokering operations), or receive precontractual or commercial information on products and services provided by the data controller or third parties.

2. PURPOSE OF PROCESSING

A) For the following service purposes, without your express consent (article 6 letter b), e) GDPR): (a) meet your requirements in relation to the data controller's services; (b) fulfil precontractual, contractual and fiscal obligations resulting from agreements with you; (c) fulfil obligations set out in legislation, regulations, EU standards or instructions issued by authorities.

B) For the following marketing purposes, with your express consent (article 7 GDPR): (a) send you newsletters, commercial information and/or advertising material on products and services provided by the data controller by e-mail, post and/or text message and/or telephone, and to measure satisfaction with service quality; (b) send you commercial information and/or advertising material provided by third parties (e.g. business partners) by e-mail, post and/or text message and/or telephone.

3. METHOD AND DURATION OF PROCESSING

Processing personal data includes the gathering, logging, organisation, classification, storage, adaptation, modification, extraction, consultation, use, transmission, circulation of the data, or any other type of distribution, comparison, interconnection, restriction, deletion or destruction operations. Your personal data will be processed in paper, electronic and/or automated format. The data controller will process the personal data for the time required for the aforementioned purposes, and the time stipulated by legislation for service purposes, but for no longer than 5 years from the date when the data were collected for marketing purposes.

4. DATA ACCESS

Your personal data may be made accessible for the purposes set out in section 2 to: (i) the data controller's employees and collaborators, in their capacity as parties authorised by the data controller and/or system administrators; (ii) third parties (for example professional firms, consultants) to whom the data controller has outsourced operations, in their capacity as data processors.

5. DATA COMMUNICATION

The data controller can disclose your personal data to third-parties for the purposes outlined in section 2.A), without your express consent (as per article 6 letter b) and c) GDPR), such as when disclosure is compulsory by law (supervisory and inspection bodies e.g. as part of anti-money laundering procedures): said third-parties will process the data as separate data controllers. Your data may be disclosed to the following parties with your consent, to facilitate and enable business transactions: (i) other brokers (and companies) identified by the data controller to collaborate on service implementation; (ii) banks and other financial institutions for the purpose of financing requests in relation to business brokered by the data controller; (iii) notaries to arrange legal documents and/or actions regarding the service assigned to the data controller; (iv) companies and/or professionals providing services to complete technical/land registry/construction/planning administration; (v) insurers for policies covering the operations carried out by the data controller. The parties in the aforementioned categories will use the data in accordance with legislation, or specific consent, as separate data controllers, given that they are extraneous to the original processing carried out by the data controller, or as data processors. You can contact the data controller at any time for a current list of the parties to whom your data will be disclosed. Your data will not be publicised.

6. NATURE OF DATA PROVISION AND CONSEQUENCES OF REFUSAL

Providing personal data for the service purposes outlined in section 2.A) is compulsory. Without this data we will be unable to guarantee the services indicated. However, providing personal data for the service purposes outlined in section 2.B) is optional. You may decide not to provide any data or subsequently refuse to let data already provided be processed. In such cases you will not receive newsletters, commercial information or advertising material on products and services provided by the data controller or, depending on the consent given, third parties. You will however continue to receive the services outlined in section 2.A).

7. RIGHTS OF DATA SUBJECTS (ARTICLES 15-21 GDPR)

(A) The right to obtain confirmation on whether or not your personal data is being processed and, if so, obtain access to your data and the following information: (a) the purpose of the processing; (b) the categories of personal data concerned; (c) the recipients or categories of recipient to whom personal data have been or will be disclosed; (d) where possible, the envisaged period for which the personal data will be stored or, if this is not possible, the criteria used to determine that period; (e) the right to lodge a complaint with the data protection supervisory authority; (f) if the data have not been collected from the data subject, any available information on their source; (g) the existence of automated decision-making, including profiling and, in such cases, meaningful information on the logic involved, and the significance and envisaged consequences of such processing for the data subject;

(B) the right to obtain the rectification of inaccurate data and the completion of incomplete data;

(C) the right to obtain the erasure of personal data (right to be forgotten) if: (a) the personal data are no longer necessary in relation to the purposes for which they were collected or otherwise processed; (b) you withdraw the consent on which processing is based and there is no other legal ground for the processing; (c) you object to the processing and there are no overriding legitimate grounds for the processing; (d) the personal data have been unlawfully processed; (e) the personal data have to be erased for compliance with a legal obligation;

(D) the right to obtain the restriction of processing if: (a) you contest the accuracy of the personal data, for a period enabling the controller to verify the accuracy of the personal data; (b) the processing is unlawful and you oppose the erasure of the personal data and request the restriction of their use instead; (c) the controller no longer needs the personal data for the purposes of the processing, but you require the data for the establishment, exercise or defence of legal claims; (d) you have objected to processing, pending the verification on whether or not the legitimate grounds of the controller override those of the data subject;

(E) the right to data portability, in other words (a) the right to receive your personal data in a structured, commonly used and machine-readable format to transmit the data to another controller, and (b) the right to have your personal data transmitted directly to another controller, where technically feasible;

(F) the right to object at any time to all or some processing of your personal data for the transmission of advertising material or direct sales, the completion of market research, or commercial communication by automated means. The right to object for direct marketing purposes also extends to conventional methods, and the data subject still has the right to object only to partial processing.

8. EXERCISING YOUR RIGHTS

You can exercise your rights by writing to the data controller's address at (P.zza Volontari della Libertà n. 8, Busto Arsizio (VA)) or sending an e-mail to: info@trascoworks.it

9. DATA PROCESSOR AND CONTROLLER

As stated previously, the data controller is Trasco S.r.l. An up-to-date list of data processors is held at the data controller's premises.

I, the undersigned, having read the privacy notice issued by the data controller Trasco S.r.l.:

[...] consent / [...] do not consent to my personal data being disclosed to third parties (other brokers, banks and financial institutions, notaries, technical consultants, insurers) for the purposes related to the data controller's brokering operations. Note: failing to give consent may result in the data controller being unable to provide the brokering services.

[...] consent / [...] do not consent to my personal data being processed for the purpose of the data controller's marketing activities (sending e-mails, postal communications, text messages, telephone calls, newsletters, commercial information on the services provided by the data controller and the measurement of satisfaction with the service quality).

[...] consent / [...] do not consent to my personal data being processed for the purpose of marketing activities by third parties or partners of the data controller (sending e-mails, postal communications, text messages, telephone calls, newsletters, commercial and/or promotional information).

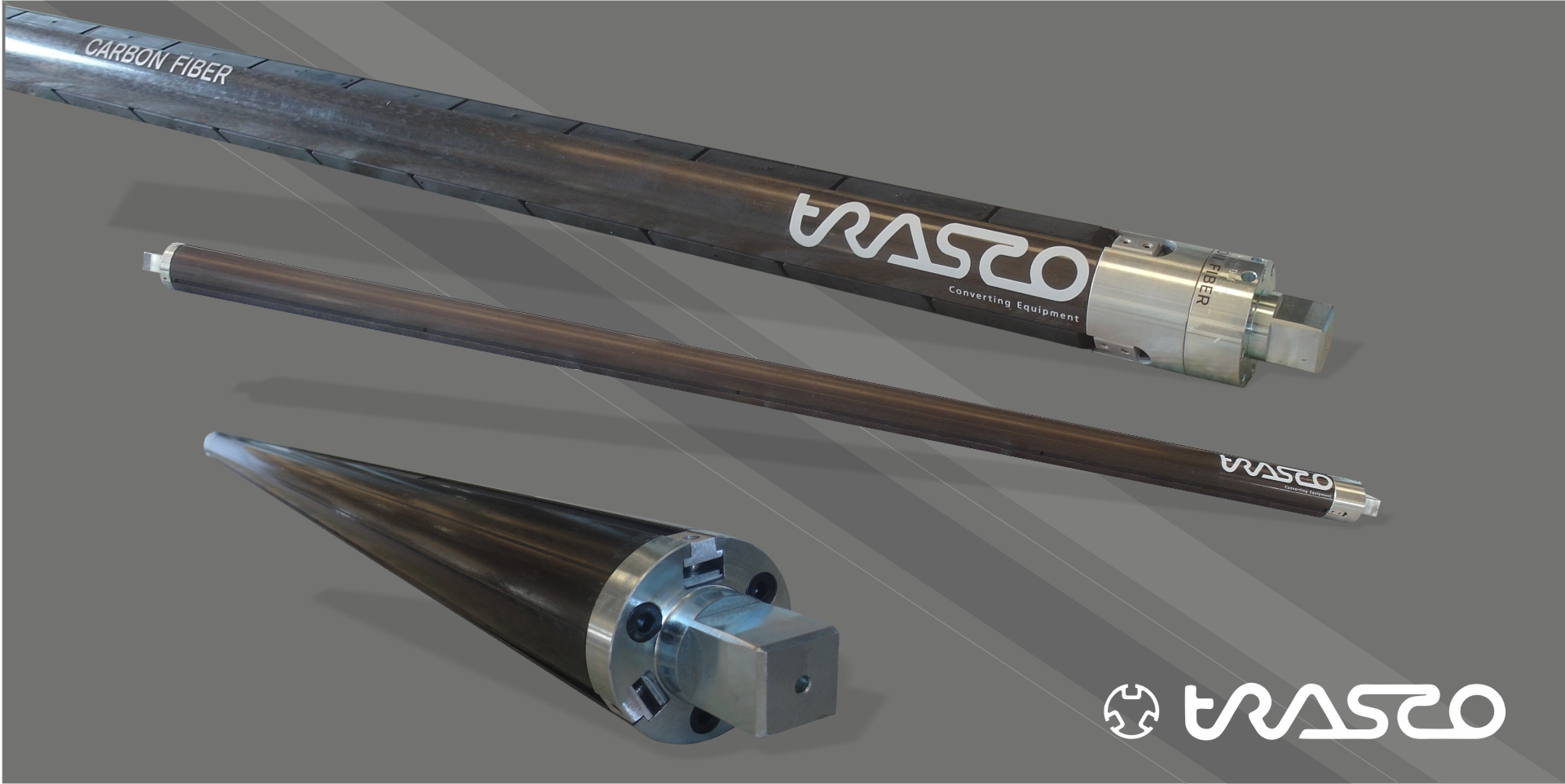

![]() Thanks to the pultrusion technique, TRASCO obtains carbon fibre bars in the desired format, prepared for assembling pneumatics. As a result, TRASCO eliminates the need for any type of machining from the production process, keeping the fibres intact such that product performance is not compromised, and reducing costs and timescales.

Thanks to the pultrusion technique, TRASCO obtains carbon fibre bars in the desired format, prepared for assembling pneumatics. As a result, TRASCO eliminates the need for any type of machining from the production process, keeping the fibres intact such that product performance is not compromised, and reducing costs and timescales.

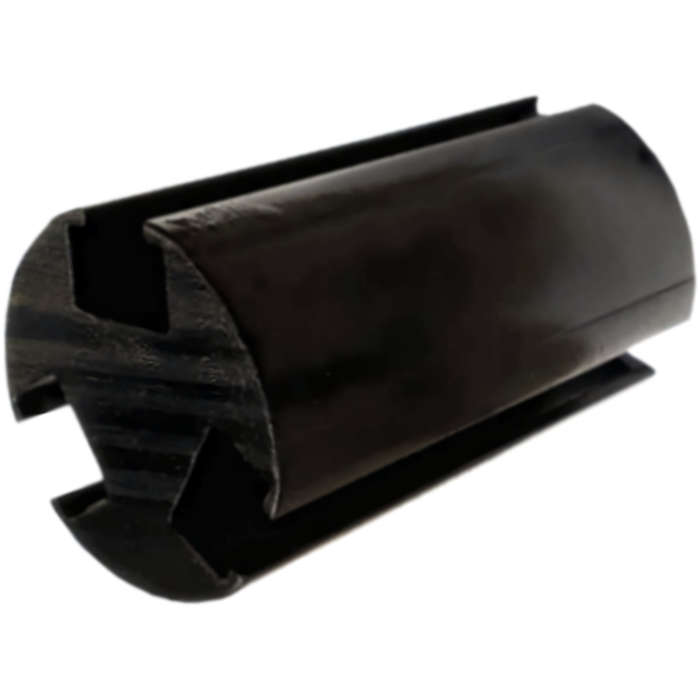

![]() Expansion with continuous strips helps to reduce the weight of the expanding shaft. A central chamber, which is typical of expansion with keys and is very heavy, is not used.

Expansion with continuous strips helps to reduce the weight of the expanding shaft. A central chamber, which is typical of expansion with keys and is very heavy, is not used.

![]() Expansion with continuous strips makes maintenance operations for the expanding shaft extremely quick and easy.

Expansion with continuous strips makes maintenance operations for the expanding shaft extremely quick and easy.

![]() 66% più leggero;

66% più leggero;![]() 23% più resistente a flessione (a parità di carico applicato).

23% più resistente a flessione (a parità di carico applicato).![]() 83% lighter;

83% lighter;![]() 28% more flexural strength.

28% more flexural strength.